TECHNOLOGY

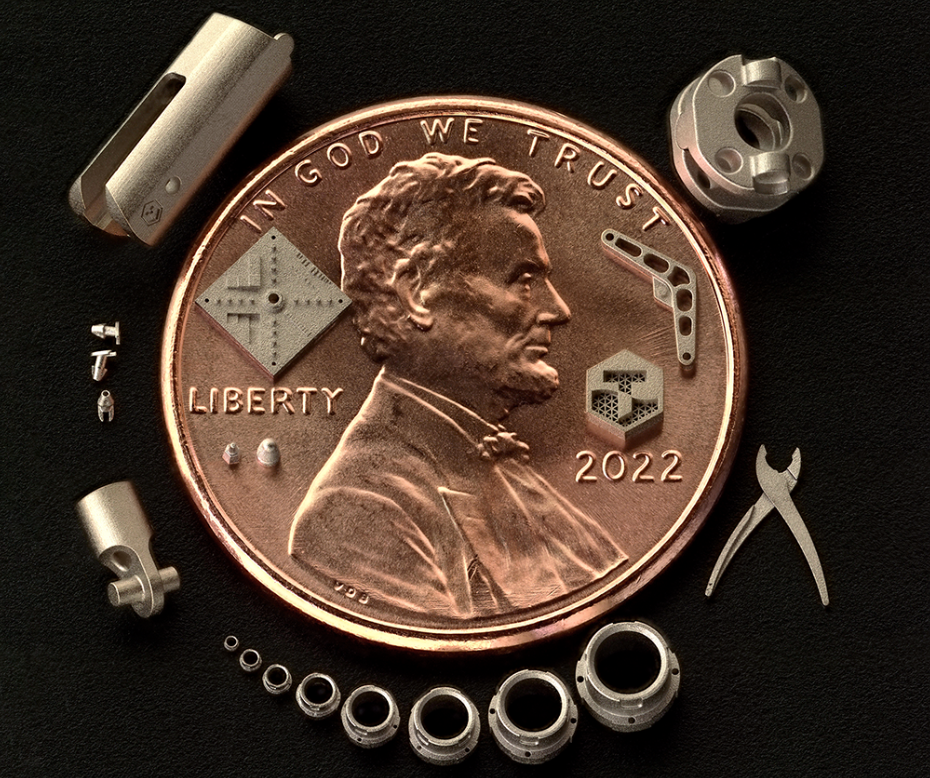

Unlocking Medical Innovation with Micro-Precision Metal Components

No other metal manufacturing process can meet Trio's precision, speed, cost, and quality.

CNC Machining and injection molding have long lead times and cumbersome design constraints. Use the first micro-scale metal additive manufacturing technology with the precision of CNC to solve your product development and manufacturing challenges.

This is Micro Manufacturing Evolved

Current precision CNC machining and metal injection molding solutions have limitations in setup costs, lead times, and complexity that can become a liability. Unlock your competitive advantage with the latest innovation in micro precision technology.

Unsurpassed Precision

The first metal 3D printing process with Ra32 native surface finish and tolerances as tight as 0.0005"

Design Flexibility

Move beyond machining & molds. Our technology allows you to design to the problem, not the process!

Speed, Speed, Speed

Whether you need protos for R&D or a production run, our technology can meet your needs!